By now, how the Covid-19 pandemic affected every industry and aspect of life worldwide, is old news. Unfortunately, though improving, the effects of the pandemic persist. The coronavirus first brought ordinary lives and daily routines to a grinding halt in an attempt to slow the spread of the highly infectious disease.

By now, how the Covid-19 pandemic affected every industry and aspect of life worldwide, is old news. Unfortunately, though improving, the effects of the pandemic persist. The coronavirus first brought ordinary lives and daily routines to a grinding halt in an attempt to slow the spread of the highly infectious disease.

The scale of disruption the pandemic caused spared no one and nothing. Overtaxed healthcare systems faltered in many areas, rural and urban, from a lack of space, trained personnel, and supplies. Government-mandated closures forced local businesses, from hair salons and movie theaters to bookstores, coffee shops, and shopping malls to shut down. Schools were closed and shifted to distance learning. With warehouses closed and meatpacking facilities in lockdown, essential businesses struggled to maintain supply lines.

Supply Chain Disruption

The pandemic produced a ripple effect for U.S. manufacturers that revealed a lack of redundancy and transparency in the supply chain. Supply chain disruption led some manufacturers to report delivery delays from weeks to possibly months. With supply line disruptions, attempting to maintain production levels to meet demand meant finding alternative suppliers at an increased cost, which some manufacturers forced on customers.

The pandemic also has created a labor shortage. Two years into the pandemic and businesses continue to struggle to recruit and retain workers. Closures, lockdowns, slowdowns and reduced hours led to workers leaving their jobs in record numbers. Dubbed the “Great Resignation,” it’s not that people have stopped working. They’ve been more selective, have found better-paying jobs or started their own businesses. Manufacturers are still having difficulty attracting the qualified workers that they need.

The manufacturing and fabrication industries were no less affected by the pandemic. Between supply chain issues, disrupted production, increased demand, forced shutdowns, and even labor shortages, the pandemic added to existing challenges in manufacturing cycles and processes. Many of these industries found themselves caught between lack and want in accessing upstream material to fulfill downstream demand for finished products. It was certainly no different for spring manufacturers suddenly confronted with a scarcity of raw materials coupled with significant price increases.

Impact on Spring Manufacturers

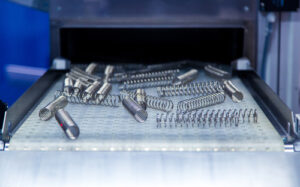

Spring and wire manufacturing and fabrication are vital for the continued production of products across numerous industrial sectors. Heavy and light gauge springs of all designs and sizes in a range of materials are integral components used by manufacturers. Even a shortlist of products made with spring parts and components is exhaustive.

The pandemic impacted the production cycles of springs used in the manufacture of machines, machinery, tools, and equipment for industrial and agricultural production, and residential, commercial, industrial, and heavy construction; for countless medical devices and equipment that rely on spring components, for various durable goods and everyday household products, as well as those springs required for computers, cell phones, and electronics. Automotive production slowed as the common spring components for fuel and drive systems, open and close mechanisms, suspension systems, fasteners, harnesses, precision and clamp parts were suddenly placed on backorder. The same and similar backorders on spring components occurred throughout the transportation sector—rail, trucking, shipping, and aerospace. spring manufacturers have been

James Spring & Wire

In these unprecedented times, James Spring has persevered. As an essential business, we were fortunate to have an extensive stock of many raw materials on hand at our facility that have allowed us to continue to meet the demands of our customers. This, in turn, allows us to continue to stay competitive with our prices and even reduce lead times in many cases.

From interrupting daily routines to disrupting global commerce, the pandemic affected all areas of life everywhere. For spring manufacturers, the economic slowdown caused by the disruption to supply chains created uncertainty for many companies that were forced to increase prices and delay and, sometimes, cancel orders. Through it all, James Spring has carried on throughout the pandemic to provide fabricators, engineers, and design firms with the best custom spring and wire forms for their applications at competitive and affordable prices.