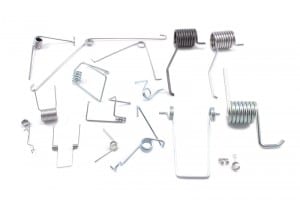

Torsion springs are helical springs, also known as coil springs. They are designed to exert torque in a radial direction. They are the opposite of compression springs which are designed to keep mechanisms apart. Torsional springs hold two mechanisms together and their tightness is proportional to the energy stored inside of it. Tension must be removed in order for the spring to release this stored energy.

Single & Double-Helical Spring Configurations

We carefully manufacture single-bodied and double-helical torsion springs with different end configurations including straight, offset, and hinge ends. Based on your custom application needs, torsion springs can be produced with wire diameters ranging from 0.005″ to 0.250″, and designed to rotate either counter-clockwise or clockwise. Operating environment, life expectancy, and spring load are taken into account when designing your custom springs. Our design allows torsion springs to be used in the direction that winds the coil. Generally, a torsion spring is used over a shaft or arbor, so when selecting the appropriate mandrel size we recommend allowing roughly 10% clearance for various deflections. If your application requires a high deflection, a reduction in mandrel size is suggested to ensure proper performance.

We carefully manufacture single-bodied and double-helical torsion springs with different end configurations including straight, offset, and hinge ends. Based on your custom application needs, torsion springs can be produced with wire diameters ranging from 0.005″ to 0.250″, and designed to rotate either counter-clockwise or clockwise. Operating environment, life expectancy, and spring load are taken into account when designing your custom springs. Our design allows torsion springs to be used in the direction that winds the coil. Generally, a torsion spring is used over a shaft or arbor, so when selecting the appropriate mandrel size we recommend allowing roughly 10% clearance for various deflections. If your application requires a high deflection, a reduction in mandrel size is suggested to ensure proper performance.

At James Spring & Wire, we offer springs in a variety of materials and sizes for your convenience – we want to be your one-stop shop for any of your spring needs. There are several materials to choose from, including Beryllium Copper, Elgiloy, Hastelloy, Chrome Silicone, Chrome Vanadium, and much more.

Customized Surface Treatment Options

Need surface treatment for your torsion springs? James Spring & Wire has the capability to provide several surface treatment options for your springs, including anodizing, bead blasting, passivation, electro-polish, powder coating, rust prevention, deburring, color coding, laser etching, and more. We also offer torsion spring plating, with finishes such as black oxide, cadmium, chrome, gold, nickel, phosphate, tin, and zinc.

As an ISO-certified torsion spring manufacturer, our quality control is second to none. We are proud to offer nothing but the highest quality springs and torsion spring treatments for all your application needs. Contact us today to learn more!